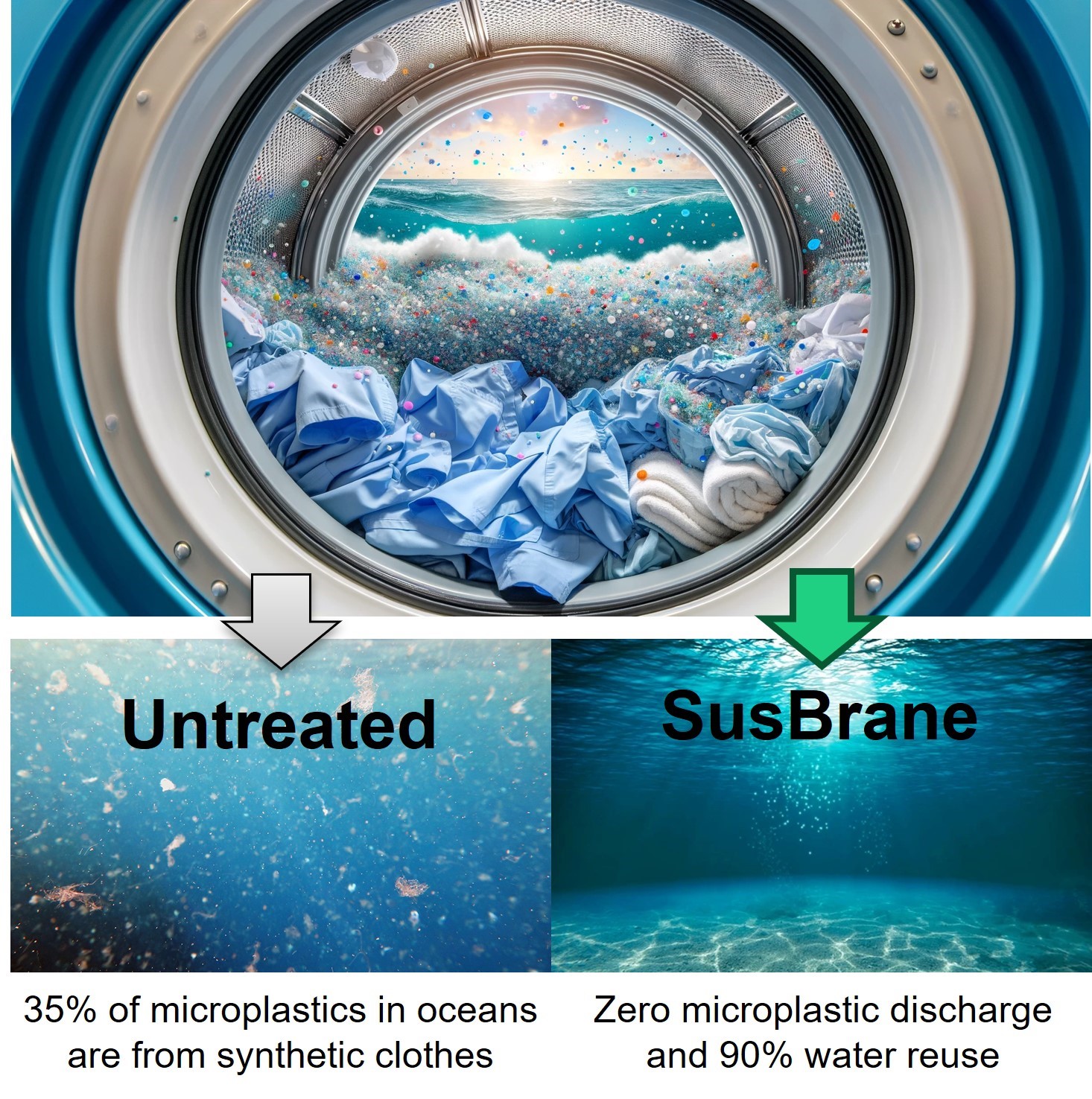

Advancing Membrane Technology for industrial water reuse, energy saving and zero microplastic discharge

We use artificial intelligence (AI) to translate the content on our website. This web page has been machine translated. If there are any uncertainties, please refer to the Danish text.

November 29. 2023